JIE intelligent transmission solution releases JIE intelligent transmission solution

complete information

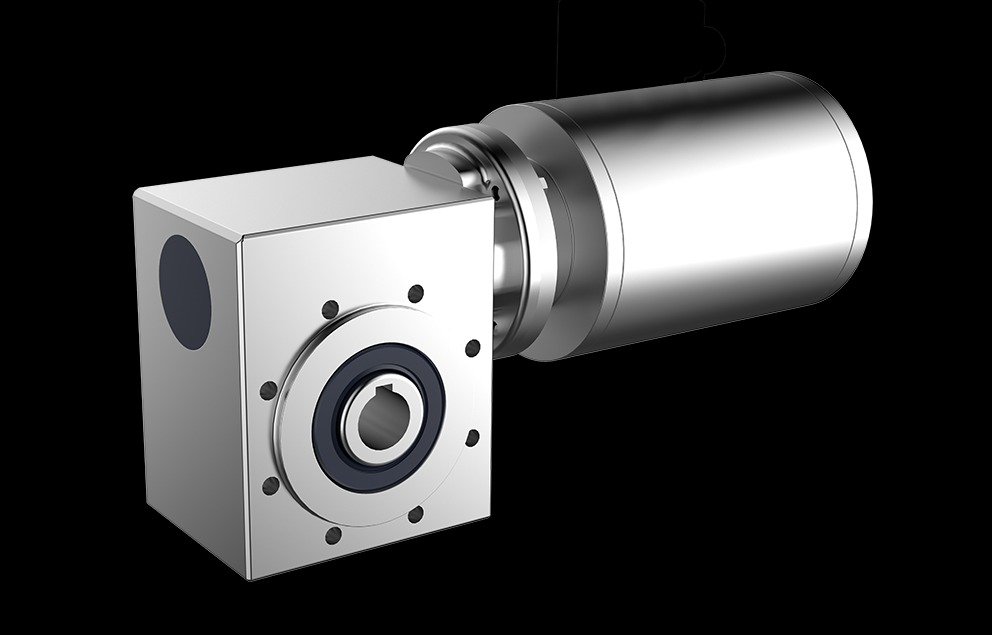

JRES Stainless Steel Gearmotors: Where Hygiene Meets High-Tech Muscle

In the realm of motor technology, the JRES Stainless Steel Gearmotor stands as a shining example of where robust engineering meets meticulous hygiene. Forget your run-of-the-mill gearboxes – these are workhorses crafted for the most demanding environments, where cleanliness and performance are equally paramount.

Stainless Steel Prowess:

The heart of the JRES lies in its exceptional material – AISI 304 stainless steel. This isn't just a cosmetic perk; it's a deliberate choice for superior:

Corrosion resistance: Say goodbye to rust and pitting, even in high-chlorine environments like food processing or marine applications.

Chemical resilience: From acidic cleaners to caustic solutions, JRES motors shrug off aggressive chemicals like Teflon shrugs off spills.

Easy cleaning: No nooks or crannies for bacteria to hide. Smooth surfaces facilitate thorough sanitation, crucial for hygiene-sensitive industries.

Beyond the Material:

But JRES isn't just about a tough exterior. These motors boast an array of tech-driven features that elevate them to the top of the food chain:

Precision gearing: Helical, bevel, and worm configurations offer optimal torque-to-speed ratios, ensuring smooth, controlled operation with minimal noise.

IP66/IP69K ingress protection: Dust and watertight, these motors can withstand even the most rigorous washdowns.

High efficiency: Advanced design minimizes energy consumption, reducing operating costs and environmental impact.

Low-maintenance: Lubricant-free options and sealed bearings significantly lower maintenance requirements.

Case Studies: Hygiene in Action:

JRES motors aren't just theoretical marvels; they're powering real-world success stories:

Food & Beverage Giant: A leading juice manufacturer replaced their carbon steel gearmotors with JRES in their bottling line. The result? Zero product contamination incidents, reduced cleaning downtime, and extended motor lifespan.

Pharmaceutical Pioneer: A renowned drug manufacturer needed reliable motors for their sterile environment. JRES, with its easy cleaning and chemical resistance, proved the perfect fit, safeguarding product purity and ensuring regulatory compliance.

Data-Driven Expertise:

JIE Group, the brains behind JRES, doesn't just manufacture; they innovate. Their R&D team, armed with advanced simulation tools and real-world testing data, continuously optimizes every component, ensuring:

Optimal gear tooth profiles: Minimizing noise and vibration for quieter operation.

Advanced bearing selection: Ensuring superior load capacity and extended lifespan.

Thermal management optimization: Preventing overheating and maximizing efficiency.

The JRES Advantage:

JRES Stainless Steel Gearmotors aren't just about hygiene; they're a testament to JIE Group's unwavering commitment to:

Uncompromising quality: Built for the toughest environments, with materials and engineering that stand the test of time.

Tech-driven innovation: Constant research and development push the boundaries of performance and efficiency.

Partnerships for success: Working closely with clients to understand their unique needs and deliver customized solutions.

When you choose JRES, you're not just getting a motor; you're getting a reliable partner in your pursuit of operational excellence and uncompromising hygiene. So, step into the future of motion control with JRES and experience the power of stainless steel innovation.

-

Authenticated user

-

Authenticated user

JIE intelligent transmission solution releases JIE intelligent transmission solution

hot news

- Research丨Lv Tie, a researcher from the Academy of Social Sciences, visited JIE for research and guidance >

- Academician|Mathematician Academician Sun Binyong inspects JIE future factory >

- Research | Lu Wuhu, vice chairman of the Municipal Federation of Trade Unions, investigates the JIE future factory >

- Research | Li Yongwei, Director of the Technological Innovation Department of the Provincial Department of Economics and Information Technology, investigates the future factory of JIE >

- Research | District Science and Technology Bureau Secretary Cao Xiaoxiang investigates JIE future factory >

- 33 | There is a kind of happiness called party care >

-

- Sharing Center

- Member Sharing

- Exclusive Sharing

- Public Sharing

Official Website

Official Tiktok

Official WeChat

Copyright © 2022 Hangzhou Jie Drive Technology Co., Ltd. Zhejiang ICP No. 16044538-4

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat