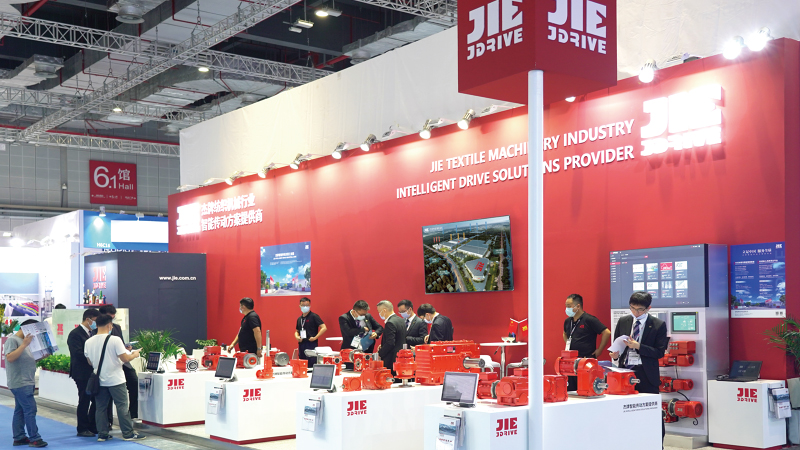

Salute to the supplier! Promote industrial alliances and achieve win-win cooperation; integrate excellent suppliers to build an industrial ecosystem for JIE intelligent Drive; we are committed to making suppliers satisfied and happy. Ingenuity and wisdom, thank you!

complete information

JIE Procurement

Industry alliance win-win cooperation

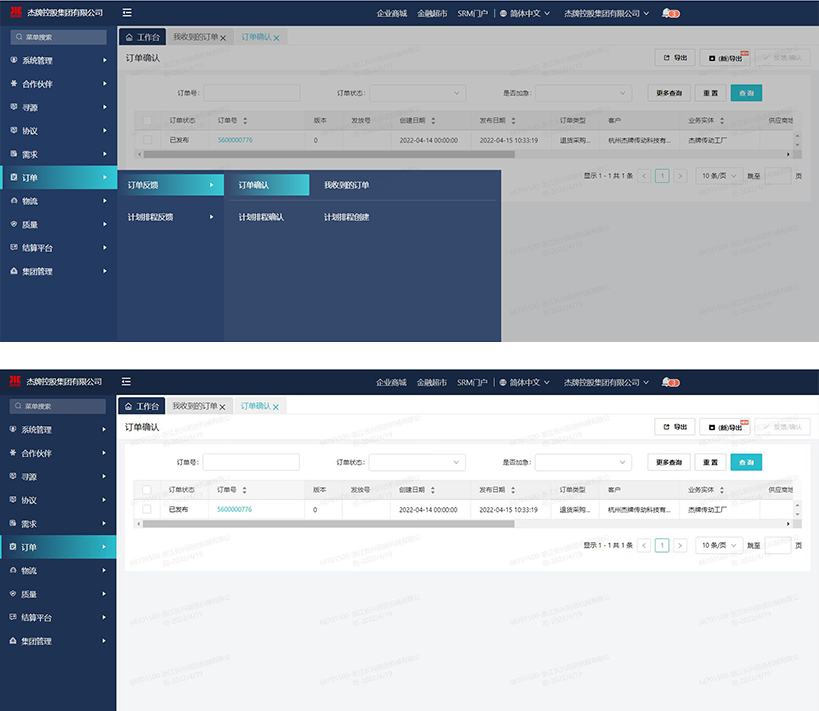

OrderApply Online More Orders

Click to applyMy OrderOnline order one-click direct access

Click to view

CooperateJoin online for double win

Click to cooperateAdvantages of joining

1. The huge market ratio effect of the gear industry

1. The huge market ratio effect of the gear industry 2. Improve product quality level

2. Improve product quality level 3. Enhance the brand influence of the industry

3. Enhance the brand influence of the industry 4. Sustainable development of the enterprise and considerable cooperation prospects

4. Sustainable development of the enterprise and considerable cooperation prospects

Affiliate Policy

-

- Basis for cooperation

- Match of major

- Similar ideas

- Comparable in size

- Reliable quality

- Reasonable price

- High-level concern

-

- Cooperation requirements

- Project management

- System management

- Lean management

- Quality assurance

- Delivery guarantee

- Service Guarantee

-

- Cooperative review

- Catalog review

- Bid review

- Entry review

- Contract review

- Pay review

- Regular review

-

- Cooperation agreement

- Integrity agreement

- Confidentiality agreement

- Technology Agreement

- Quality agreement

- Supply agreement

- Supplementary agreement

-

- Cooperation Process

- High-level mutual visit project launched

- Requirement Confirmation Plan Confirmation

- Sample order cooperation sample order confirmation

- Small batch cooperation Small batch confirmation

- Batch cooperation Batch confirmation

WELOME TO JOIN US!

Bidding InformationPost online purchase order

-

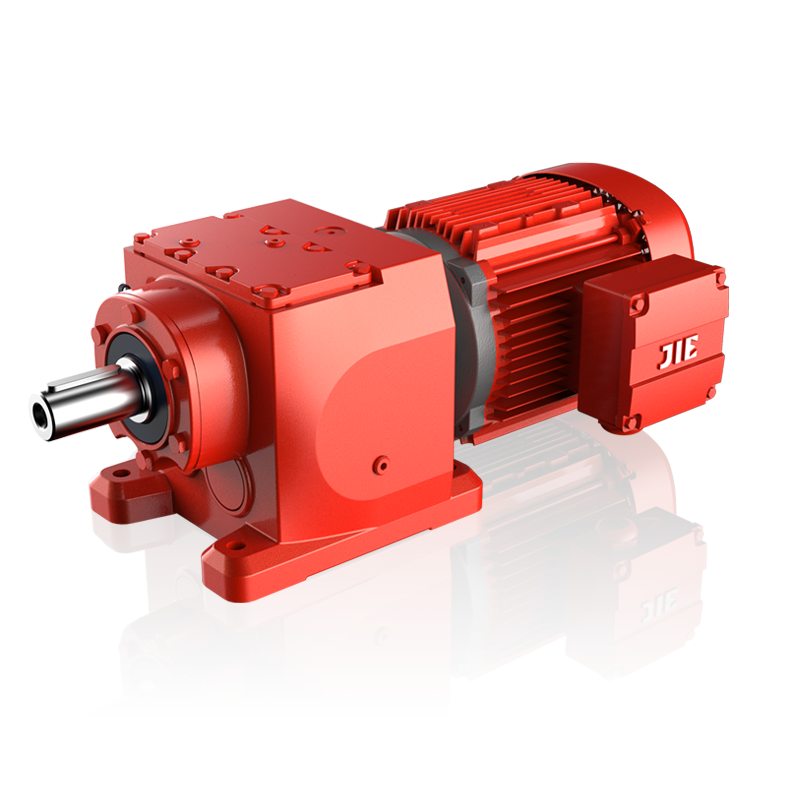

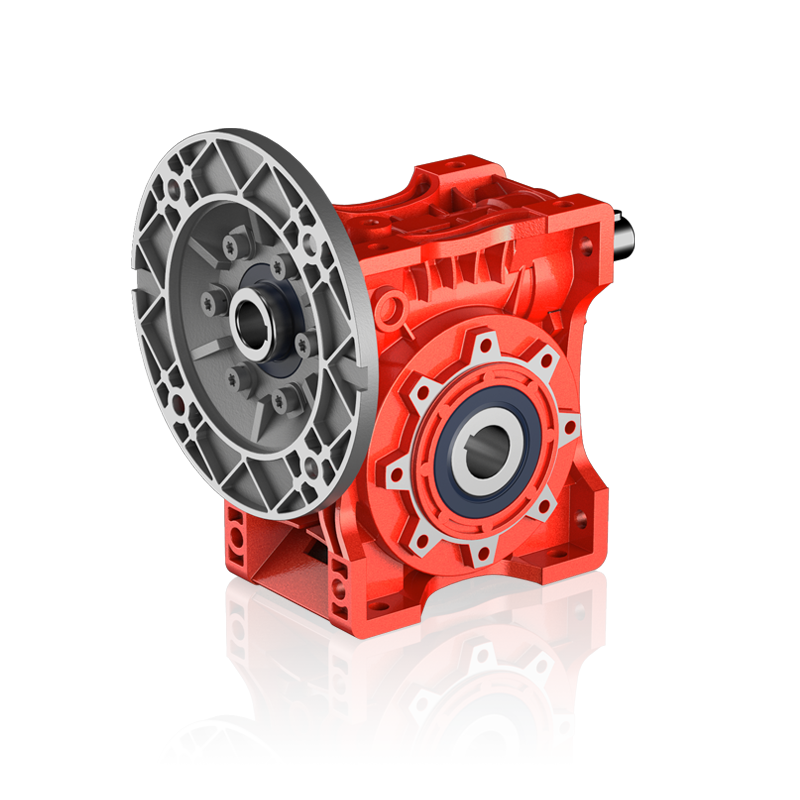

External material (aluminum casting): reducer box, flange end cover

1. Material: ADC12

2. Range: 0.5-10kg

3. Annual consumption: 3000 tons -

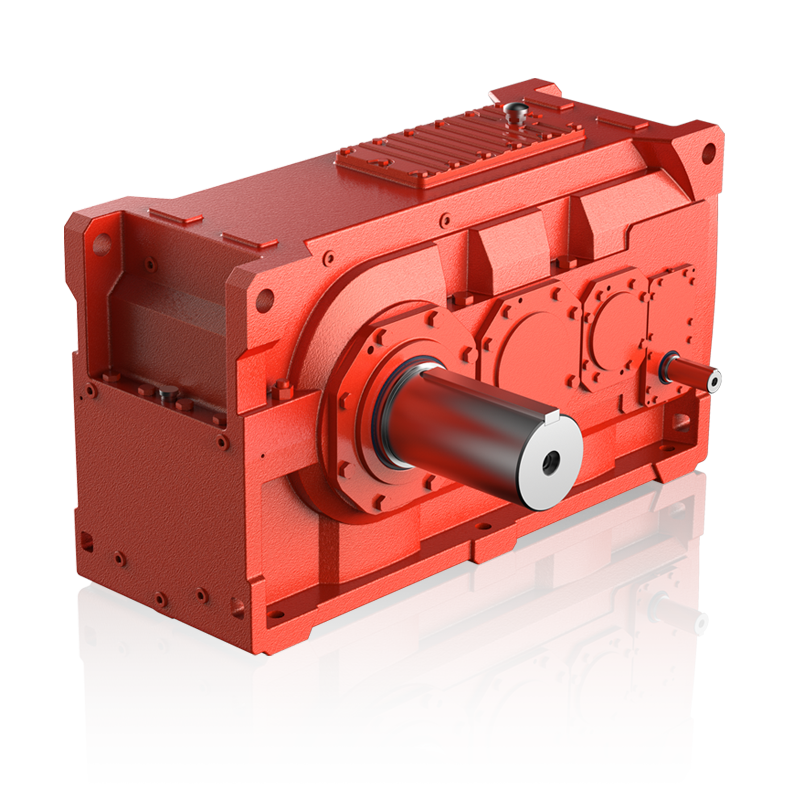

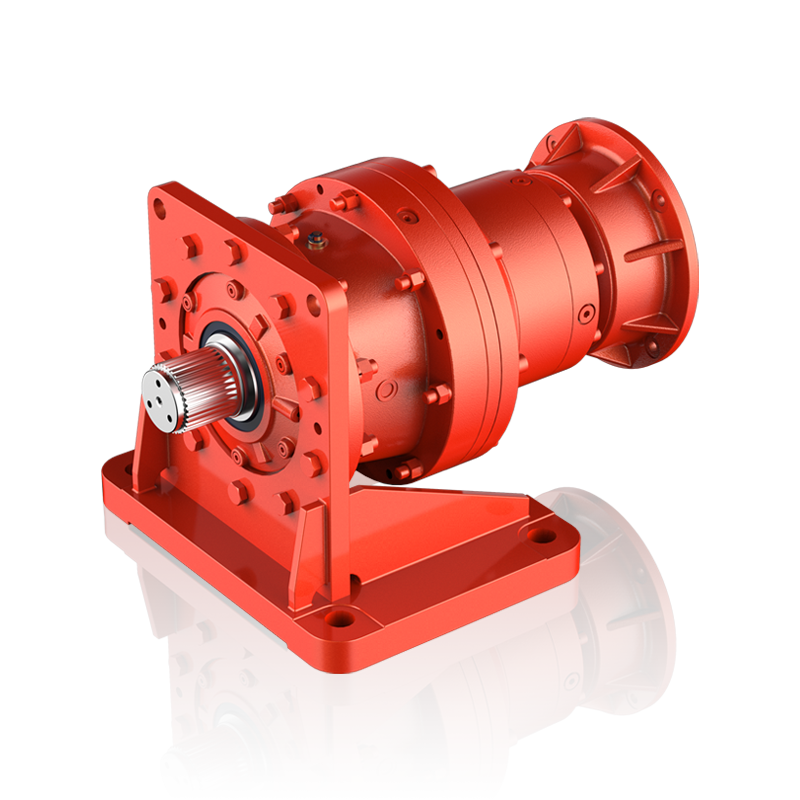

External material (iron casting): reducer box, motor frame, flange end cover

1. Material: HT200/HT250/QT450

2. Range: 0.5-1000kg

3. Annual consumption: 50,000 tons -

Internal material (forging): reducer gear, gear shaft forging

1. Material: 20CrMnTi

2. Range: φ160-φ500

3. Annual consumption: 300,000 pieces -

Internal material (worm gear): reducer worm gear

1. Material: tin bronze

2. Range: 1.75-7.5 modulus

3. Annual consumption: 150,000 pieces -

Internal material (helical gear pair): helical gear pinion

1. Material: 20CrMnTi

2. Range: 1-10 modulus

3. Annual consumption: 5 million pieces -

Internal material (bevel gear pair): bevel gear pair - ground & non-ground

1. Material: 20CrMnTi

2. Range: 2.12-10.28 modulus

3. Annual consumption: 200,000 sets -

Internal material (shaft): reducer input shaft, output shaft

1. Material: 40Cr

2. Range: φ25-φ250

3. Annual consumption: 1.2 million -

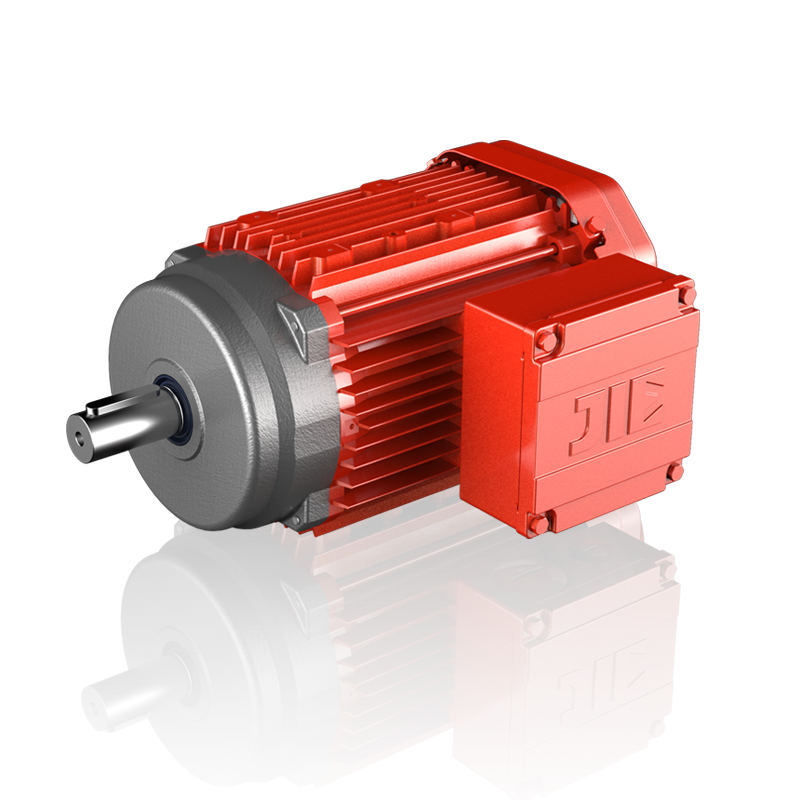

Internal material (shaft): motor rotor shaft

1. Material: 45#

2. Range: φ20-φ100

3. Annual consumption: 1 million -

Standard material (steel): gear steel

1. Material: 20CrMnTi

2. Range: φ30-φ150

3. Annual consumption: 1500 tons

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat