JIE intelligent transmission solution releases JIE intelligent transmission solution

complete information

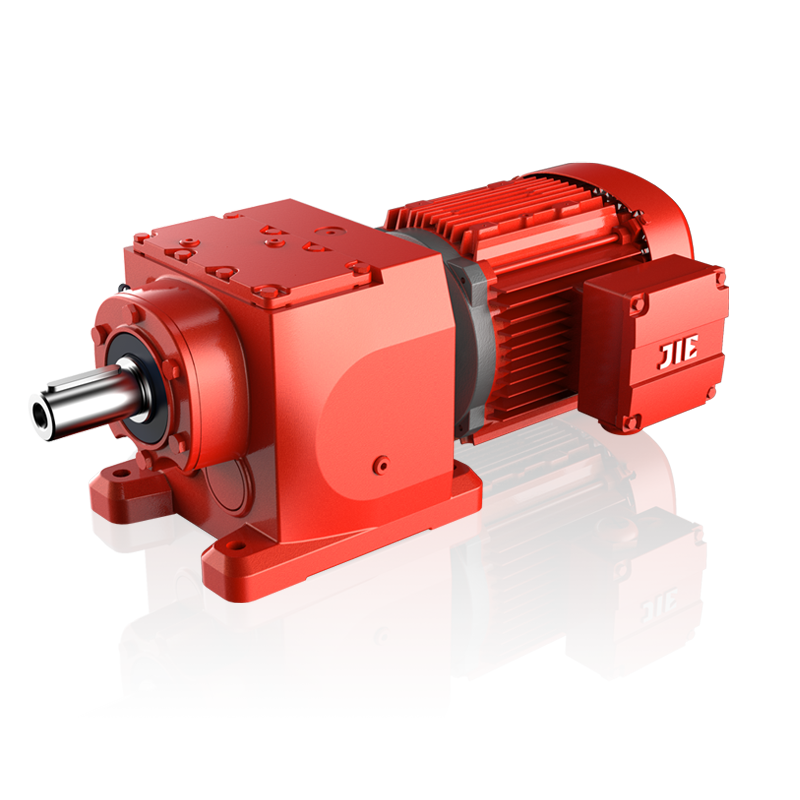

Jie Drive JRT Gearmotor Type

JRT Gearmotor

The JRT gearmotor is a power transmission product that reduces motor rotational speed and increases torque. It offers higher efficiency and reliability than an electric motor. It also provides a range of power levels and output torques.

The JRT Helical-Worm Gearmotor is a modular design that can be customized to meet the needs of your application. This includes input interfaces, output modules and installation types.

JRTR helical inline gearmotor

The JRTR gearmotor is a compact drive with a gear unit and integrated electric motor. Its constant high quality and competitive pricing make it the appropriate drive for many applications. It is produced according to the tried and tested UNICASE housing principle. The modular design allows customer specific executions to be assembled from stock. It can be configured with feedback devices, including TTL, HTL, resolver, BiSS, and Hiperface. In addition, it can be supplied with custom flanges and shafts. It can also be supplied with food grade lubricants and extra environmental protection for use in washdown and corrosive environments.

Helical geared motors offer an excellent combination of power, speed, and precision. They are ideal for heavy-duty applications in industries such as cement manufacturing, power generation, and shipping. The helical teeth of the gears are meshed tightly to reduce noise and vibration and improve transmission efficiency. They are also easy to clean and can withstand high temperatures.

To ensure the optimal performance of your gearmotor, it is essential to size it correctly for your application. This can be done by assessing several critical factors, including load requirements, duty cycle, and motor overload capacity. By evaluating these factors, you can select the right gearmotor for your needs. A poorly sized gearmotor can cause damage to equipment and lead to excessive maintenance costs.

JRTF parallel shaft helical gearmotor

The JRTF series is a powerful, compact and easy to install gearmotor that has millions of combinations. Its modular design allows for the selection of the ideal combination of motor and gearbox for your application. The choice of gearbox options includes different shaft arrangements (concentric, right angle and parallel), multiple brake types (AC braking and DC braking for stagecraft), external cooling, PTC or thermal contact, and a lock down/blocking device. Its quality is assured through the use of only high-quality materials, strict production control, and carburizing for advanced gear profiles.

A gearmotor is a small electric motor (AC induction, permanent magnet DC or brushless DC) with an integral gear reducer attached. The end shield on the motor provides multiple bearing supports and a sealing provision for the gear unit, while the other side of the end shield provides the rotor or armature shaft pinion with a mounting surface. This construction eliminates the need for separate rotor and gear units, which makes these gearmotors a convenient and cost-effective solution.

Selecting the right gearmotor is essential for maximizing performance and longevity. The motor and gearhead must be correctly sized to achieve maximum efficiency and load capacity. Oversized gearmotors may overheat and damage the components, resulting in expensive maintenance and repairs. To avoid these problems, you should be familiar with the following gearmotor must-knows:

JRTK helical bevel gearmotor

Depending on the application, JRTK gearmotors can be equipped with a variety of options. These include AC braking (AC or DC), encoders in many shapes and sizes, external cooling, PTC or thermal contact, back stop, and more. These units are produced under UNI EN ISO 9001:2008 standards and deliver high quality. They use A-brand parts and precision hardened and ground gears to guarantee a long service life and low noise.

A new method for generating crowned helical gears has been developed, which provides a conjugate gear tooth surface, localized bearing contact, and reduced sensitivity to misalignment. It also allows the design of gears that have favorable shape and minimal transmission error. In addition, computer programs have been developed to simulate gear meshing and bearing contact.

The hygienic washdown design of the IE5+ motor and helical gear unit is ideal for materials handling, intralogistics, and sanitary applications. It can handle large speed ranges and a wide array of conveyor systems, including stacker cranes, automated guided vehicles, and more. Its IP69K surface treatment ensures a sterile and durable solution for wet environments.

-

Authenticated user

-

Authenticated user

JIE intelligent transmission solution releases JIE intelligent transmission solution

hot news

- Research丨Lv Tie, a researcher from the Academy of Social Sciences, visited JIE for research and guidance >

- Academician|Mathematician Academician Sun Binyong inspects JIE future factory >

- Research | Lu Wuhu, vice chairman of the Municipal Federation of Trade Unions, investigates the JIE future factory >

- Research | Li Yongwei, Director of the Technological Innovation Department of the Provincial Department of Economics and Information Technology, investigates the future factory of JIE >

- Research | District Science and Technology Bureau Secretary Cao Xiaoxiang investigates JIE future factory >

- 33 | There is a kind of happiness called party care >

-

- Sharing Center

- Member Sharing

- Exclusive Sharing

- Public Sharing

Official Website

Official Tiktok

Official WeChat

Copyright © 2022 Hangzhou Jie Drive Technology Co., Ltd. Zhejiang ICP No. 16044538-4

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat