JIE intelligent transmission solution releases JIE intelligent transmission solution

complete information

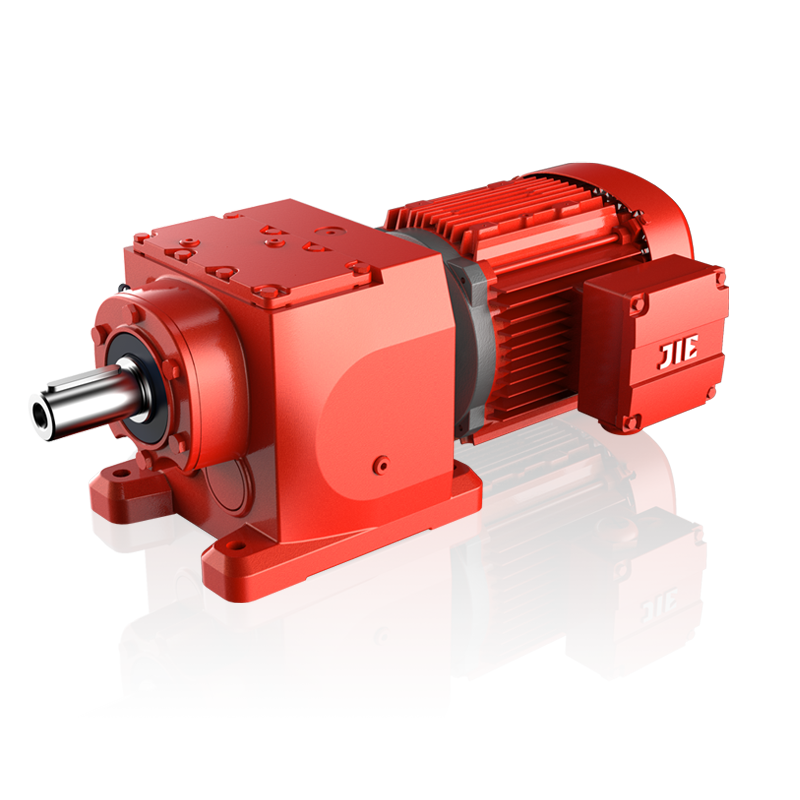

Sourcing Success: How to Choose the Right Gear Motor for Your Industrial Needs

In the intricate realm of industrial manufacturing, the selection of suitable gear motors, worm gear units, and electric motors emerges as a critical decision that profoundly impacts efficiency and performance. As a distinguished manufacturer and factory specializing in these components, we recognize the complexities that buyers face when navigating this diverse market. For instance, in a recent collaboration with a client in the textile industry, we addressed their need for precision and space optimization by recommending a specialized worm gear unit. This tailored solution not only enhanced their production efficiency but also demonstrated the importance of understanding the unique requirements of different components.

Understanding Your Requirements:

At the forefront of sourcing success lies a profound understanding of specific industrial requirements for gear motors, worm gear units, and electric motors. For example, a client in the material handling sector approached us with the need for a robust electric motor capable of handling heavy loads with variable speed control. Through a detailed analysis of their material flow dynamics, we recommended a high-torque electric motor with variable frequency drive capabilities. This solution not only met their immediate needs but also showcased the importance of aligning electric motor specifications with the intricacies of the application.

Types of Components:

Our extensive experience in manufacturing has exposed us to various types of gear motors, worm gear units, and electric motors, each tailored to distinct applications. In a recent case study, a client in the renewable energy sector sought a reliable and efficient gear motor for a solar tracking system. Leveraging our expertise, we recommended a planetary gear motor with precise control capabilities. This not only optimized the solar panel's tracking efficiency but also emphasized the significance of choosing the right gear motor type for specific applications.

Performance Considerations:

In the pursuit of sourcing success, a deep dive into performance considerations for gear motors, worm gear units, and electric motors is imperative. A recent research initiative conducted by our technical team focused on evaluating the efficiency of our worm gear units under varying loads and environmental conditions. Through controlled testing, we demonstrated the superior performance of our units in terms of torque transmission and wear resistance. This technical insight underscores the importance of data-driven decision-making, ensuring that performance considerations are backed by empirical evidence specific to each component.

Environmental Factors:

Consideration of environmental factors is paramount, especially when dealing with diverse industrial settings for gear motors, worm gear units, and electric motors. In a recent case where a client operated in a corrosive environment, our engineering team recommended worm gear units with enhanced corrosion resistance through specialized coatings and materials. By sharing real-world examples of these units thriving in similarly challenging environments, we provided the client with confidence in our solutions' durability and longevity.

Reliability and Durability:

Reliability is the cornerstone of our manufacturing philosophy for gear motors, worm gear units, and electric motors. In a recent reliability study conducted on our electric motors, utilizing advanced testing protocols, we showcased their exceptional durability and robust performance under strenuous conditions. For instance, our electric motors underwent extended stress testing, simulating continuous operation in demanding applications. The results, exceeding industry standards, reinforced the importance of prioritizing components with proven reliability. This empirical evidence translates to reduced downtime and increased operational efficiency for our clients.

Cost-Benefit Analysis:

Our commitment to providing value extends to a meticulous cost-benefit analysis for gear motors, worm gear units, and electric motors. In a real-world case, a client initially considered lower-cost electric motors for their operations. However, through a comprehensive analysis that factored in maintenance costs, energy efficiency, and expected lifespan, our team showcased the long-term economic benefits of investing in higher-quality electric motors. By presenting a detailed cost breakdown and demonstrating the potential savings over the motors' lifespan, we empowered the client to make a strategic investment decision that maximized operational benefits for each component. This case exemplifies the nuanced approach required in evaluating cost-effectiveness beyond the initial investment, specific to gear motors,

-

Authenticated user

-

Authenticated user

JIE intelligent transmission solution releases JIE intelligent transmission solution

hot news

- Research丨Lv Tie, a researcher from the Academy of Social Sciences, visited JIE for research and guidance >

- Academician|Mathematician Academician Sun Binyong inspects JIE future factory >

- Research | Lu Wuhu, vice chairman of the Municipal Federation of Trade Unions, investigates the JIE future factory >

- Research | Li Yongwei, Director of the Technological Innovation Department of the Provincial Department of Economics and Information Technology, investigates the future factory of JIE >

- Research | District Science and Technology Bureau Secretary Cao Xiaoxiang investigates JIE future factory >

- 33 | There is a kind of happiness called party care >

-

- Sharing Center

- Member Sharing

- Exclusive Sharing

- Public Sharing

Official Website

Official Tiktok

Official WeChat

Copyright © 2022 Hangzhou Jie Drive Technology Co., Ltd. Zhejiang ICP No. 16044538-4

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat