JIE intelligent transmission solution releases JIE intelligent transmission solution

complete information

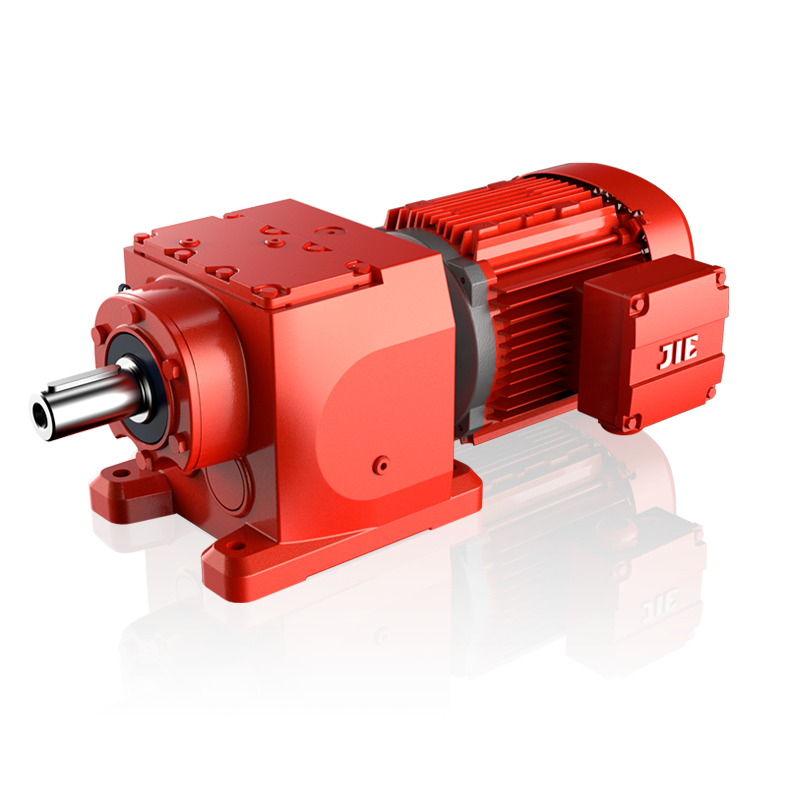

Selection of the four major series of Jie JRT(R, F, K, S hard tooth surface reduction motors)

The four series of hard-tooth surface reduction motors (R, F, K, S series reducers) manufactured by JIE reducer (JIE) are famous brand transmission products with internationally advanced levels, mainly including JRTR series helical gear reduction motors, JRTF There are four series: parallel shaft-helical gear reduction motors, JRTK series helical gear-bevel gear reduction motors, and JRTS series helical gear-worm gear reduction motors.

This series of hard tooth surface gear reduction motors follow the modular and optimized design concept, use finite element analysis technology, and adopt a unique low-noise gear tooth profile design to ensure the advancement of the design; the transmission ratio is finely graded and has millions of types Different combinations can meet various needs of users; everything from material selection to manufacturing is meticulous and strictly controlled - the box is precision one-time cast, beautiful and strong, and the gears are carburized and hardened, making them durable.

The four series of R, F, K and S reducers are processed in FMC flexible manufacturing units to achieve high precision and maintenance-free products. They are also equipped with double-type reduction motors (an additional helical gear reducer is installed at the input end), locking Discs, splined hollow shafts, B14 flanges and other combinations are available for customers to choose from.

| JRTR | F | 67 | II/G | D | 80 | N | 4 | /BMG /HF /TF | /128.97 | /M1 | /180° | |

| Code | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

Code 1: refers to the product model code

JRTR--helical gear reduction motor

JRTF--parallel shaft-helical gear reduction motor

JRTK--helical gear-bevel gear reduction motor

JRTS--helical gear-worm gear reduction motor

Code 2: refers to the product assembly type

No code - foot installation

F--flange installation

..F--foot flange installation

M--flange mounting with extended bearing housing

X--foot-mounted single-stage transmission

XF--Flange mounted single-stage transmission

A--Hollow shaft installation

AF--flange hollow shaft installation

Code 3: refers to the specification number of the reducer

67, 17, 27, 37, 47, 57, 77, 87, 97, 107, 127, 137, 147, 157, 167, 177, 187

Code 4: Refers to flange size or torque arm accessories

None - no flange, or only one flange, or the minimum flange of more than one flange

II--The large flange among the two flanges, or the medium flange among the three flanges

III--the largest flange among the three flanges

G(T)--Torque arm

Code 5: refers to the electric motor

D--Three-phase asynchronous motor (IP54)

YB--explosion-proof three-phase asynchronous motor

YGP--Frequency control three-phase asynchronous motor for roller table (can be equipped with encoder)

YZP--frequency variable speed three-phase asynchronous motor for metallurgy and lifting (can be equipped with encoder)

YVP--Frequency control three-phase asynchronous motor (can be equipped with encoder)

YD--variable pole multi-speed three-phase asynchronous motor

Code 6: Refers to the motor specification code

80, 63, 71, 90, 100, 112, 132, 160, 180, 200, 225, 250, 280

Code 7: Refers to the code for the length of the motor stator core.

D,K,N,S,M,ML,L

Code 8: refers to the number of motor poles

4-pole motor, 6-pole motor

Code 9: Refers to accessory devices

None--No accessory device

BMG-brake

HF--manual release locked in brake release position

HR--manual release, automatic return to braking position

RS--backstop

TF - thermistor protection device PTC thermistor

TH--Thermostat protection device bimetal switch

U--body cooling (no ventilation)

V--forced cooling fan 3X380-415V 50HZ AC

VS--forced cooling fan 1X220-266V 50HZ AC

VR--forced cooling fan 1X24V DC

Z--High inertia flywheel fan

C--Fan protective cover (rain cover)

Code 10: refers to the transmission ratio of the reducer

Code 11: refers to the installation position of the reduction motor

M1, M2, M3, M4, M5, M6

Code 12: Refers to the location of the junction box

0°, 90°, 180°, 270°

-

Authenticated user

-

Authenticated user

JIE intelligent transmission solution releases JIE intelligent transmission solution

hot news

- Research丨Lv Tie, a researcher from the Academy of Social Sciences, visited JIE for research and guidance >

- Academician|Mathematician Academician Sun Binyong inspects JIE future factory >

- Research | Lu Wuhu, vice chairman of the Municipal Federation of Trade Unions, investigates the JIE future factory >

- Research | Li Yongwei, Director of the Technological Innovation Department of the Provincial Department of Economics and Information Technology, investigates the future factory of JIE >

- Research | District Science and Technology Bureau Secretary Cao Xiaoxiang investigates JIE future factory >

- 33 | There is a kind of happiness called party care >

-

- Sharing Center

- Member Sharing

- Exclusive Sharing

- Public Sharing

Official Website

Official Tiktok

Official WeChat

Copyright © 2022 Hangzhou Jie Drive Technology Co., Ltd. Zhejiang ICP No. 16044538-4

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat