JIE intelligent transmission solution releases JIE intelligent transmission solution

complete information

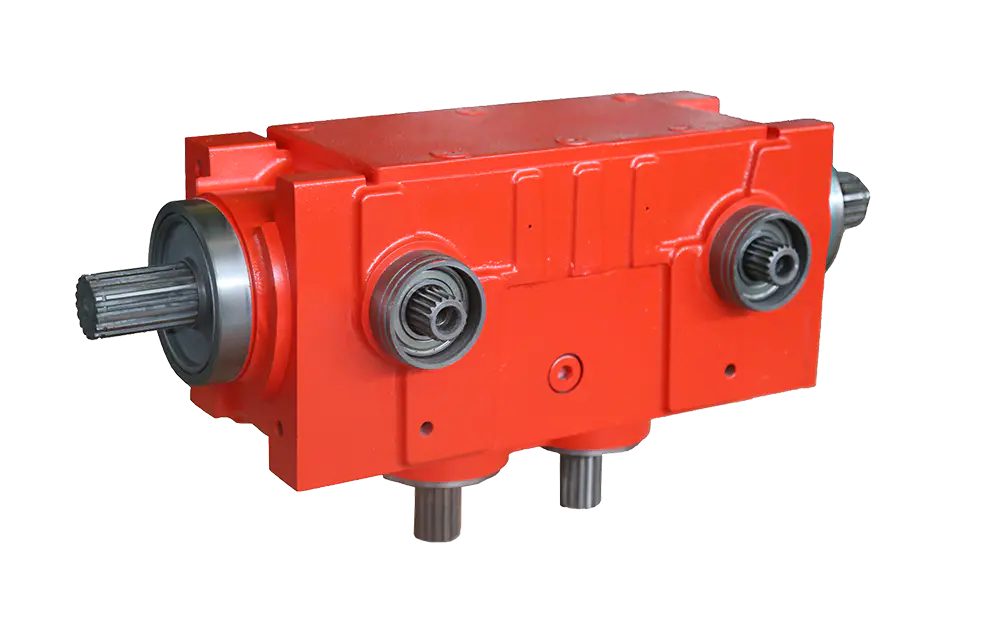

Jie Textile Machinery Speed Reducer

Textile Machinery Speed Reducer

A textile machinery speed reducer is a mechanical device that is used to reduce the speed of a motor and increase its torque. It is an important transmission component in textile machinery, and is used in a variety of applications, including:

Spinning: Speed reducers are used in spinning machines to draw, sliver, and wind yarn.

Weaving: Speed reducers are used in weaving machines to open the loom, weave the weft, and beat the weft.

Printing and dyeing: Speed reducers are used in printing and dyeing machines to dye and finish fabrics.

Knitting: Speed reducers are used in knitting machines to knit and sew fabrics.

Types of Textile Machinery Speed Reducers

There are three main types of textile machinery speed reducers:

Planetary gear reducers: These reducers are compact, have a large transmission ratio, high efficiency, and low noise. They are suitable for high-speed, heavy-duty transmission applications.

Cylindrical gear reducers: These reducers are simple in structure, have low manufacturing costs, and are suitable for low-speed, light-duty transmission applications.

Worm gear reducers: These reducers have a large transmission ratio, compact structure, and are suitable for low-speed, high-torque transmission applications.

Jie Textile Machine Gearbox

Wide Transmission Ratio: Jie gear reducer boasts a transmission ratio ranging from 0.364 to 2.33, offering great versatility for various textile machinery applications.

High Efficiency (≥96%) The impressive efficiency of reducer translates to significant energy savings and reduced environmental impact.

Input Speed Compatibility (800 rpm): Designed to handle an input speed of 800 rpm, this reducer seamlessly integrates with many common textile machinery motors.

Selection of Textile Machinery Speed Reducers

When selecting a textile machinery speed reducer, the following factors should be considered:

Transmission ratio: The transmission ratio should be selected according to the transmission requirements of the textile machinery.

Torque: The torque should be selected according to the load conditions of the textile machinery.

Efficiency: In order to save energy and protect the environment, a high-efficiency reducer should be selected.

Structure: The reducer should be selected according to the space constraints of the textile machinery.

Noise: In order to reduce work noise, a low-noise reducer should be selected.

Vibration: In order to improve the smoothness of operation, a low-vibration reducer should be selected.

Service life: In order to reduce maintenance costs, a reducer with a long service life should be selected.

Reliability: In order to improve production efficiency, a reliable reducer should be selected.

-

Authenticated user

-

Authenticated user

JIE intelligent transmission solution releases JIE intelligent transmission solution

hot news

- Research丨Lv Tie, a researcher from the Academy of Social Sciences, visited JIE for research and guidance >

- Academician|Mathematician Academician Sun Binyong inspects JIE future factory >

- Research | Lu Wuhu, vice chairman of the Municipal Federation of Trade Unions, investigates the JIE future factory >

- Research | Li Yongwei, Director of the Technological Innovation Department of the Provincial Department of Economics and Information Technology, investigates the future factory of JIE >

- Research | District Science and Technology Bureau Secretary Cao Xiaoxiang investigates JIE future factory >

- 33 | There is a kind of happiness called party care >

-

- Sharing Center

- Member Sharing

- Exclusive Sharing

- Public Sharing

Official Website

Official Tiktok

Official WeChat

Copyright © 2022 Hangzhou Jie Drive Technology Co., Ltd. Zhejiang ICP No. 16044538-4

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat