JIE intelligent transmission solution releases JIE intelligent transmission solution

complete information

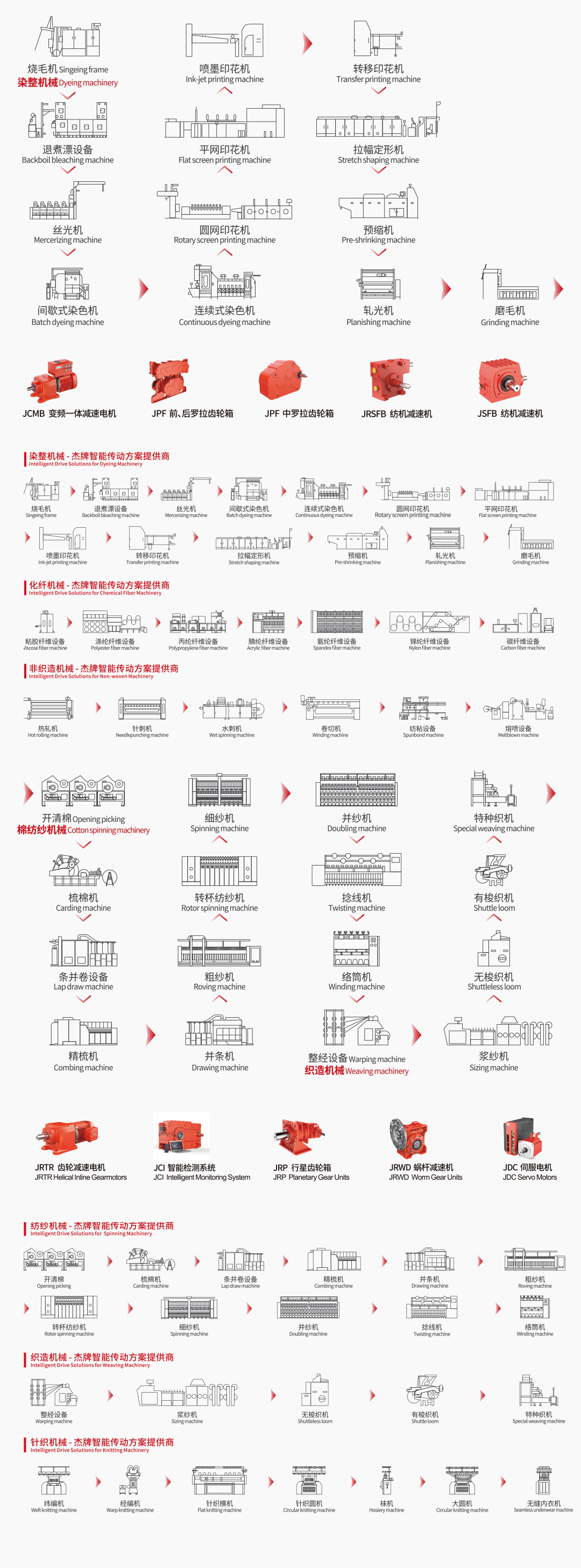

Intelligent Transmission Solutions For The Textile Machinery Industry Chain

Intelligent transmission solutions can significantly enhance the efficiency and performance of the textile machinery industry chain. Here are some key aspects to consider when implementing such solutions:

Predictive Maintenance Systems: Incorporate sensors and data analytics to monitor the condition of critical transmission components such as gear motors and worm gear units. Predictive maintenance algorithms can detect anomalies and wear, allowing for timely maintenance and reducing unplanned downtime.

A textile manufacturer implemented vibration sensors on critical gear motors and used predictive maintenance software to monitor their condition. As a result, they reduced unplanned downtime by 30% and extended the lifespan of gear motors by 15%.

Variable Speed Drives: Utilize variable frequency drives (VFDs) to control the speed of electric motors. This enables precise control over the machinery, optimizing energy consumption and reducing wear and tear on mechanical components.

For instance, during startup, VFDs can gradually ramp up motor speed, reducing the initial power surge.

Case Study: A textile factory upgraded its loom machinery with VFDs, resulting in a 20% reduction in energy consumption and improved product quality due to more consistent weaving speeds.

IoT Integration: Connect machinery to the Internet of Things (IoT) to gather real-time data on production processes. This data can be used to make informed decisions, such as adjusting machine settings for different fabrics or identifying areas for improvement.

A textile plant integrated IoT sensors into spinning machines to monitor yarn tension. This data was transmitted to a centralized control system, allowing operators to make real-time adjustments to ensure consistent yarn quality.

Remote Monitoring and Control: Implement remote monitoring and control systems, allowing operators and maintenance personnel to access machinery data and make adjustments from anywhere. This can improve response times and reduce the need for on-site visits.

A textile manufacturer with multiple production facilities implemented remote monitoring, enabling centralized control. This reduced the need for on-site staff, resulting in cost savings and more efficient resource allocation.

Energy Efficiency: Design gear motors and other transmission components with energy efficiency in mind. High-efficiency motors, regenerative braking systems, and optimized gear designs can all contribute to reduced energy consumption.After replacing outdated motors with high-efficiency models, a textile mill reduced its electricity consumption by 25% and achieved a payback period of just one year.

Customization and Flexibility: Develop modular transmission solutions that can be easily adapted to different stages of the textile production process. This flexibility can accommodate changing production requirements and reduce the need for costly machinery replacements.A textile machinery manufacturer designed modular gear units that could be easily reconfigured for different textile production processes. This flexibility allowed textile companies to adapt quickly to changing market demands without investing in entirely new machinery.

Machine Learning Algorithms: Apply machine learning algorithms to analyze historical data and optimize machine settings for specific textile types or production goals. This can lead to improved product quality and production efficiency.By applying machine learning to loom operations, a textile manufacturer improved fabric quality by 15% and reduced material waste by 10%.

Supply Chain Integration: Connect your transmission solutions to the broader textile industry supply chain. Real-time data sharing with suppliers and customers can streamline production planning and inventory management.A textile manufacturer integrated its transmission solutions with suppliers and customers through a cloud-based platform. This enabled real-time inventory tracking, resulting in reduced stockouts and overstock situations, optimizing the supply chain.

Cybersecurity Measures: With increased connectivity, prioritize cybersecurity to protect sensitive data and prevent unauthorized access to machinery controls. Implement robust security protocols and stay updated on cybersecurity best practices.A textile machinery factory implemented comprehensive cybersecurity measures, preventing a potential cyberattack that could have disrupted production and safeguarding critical manufacturing data.

Operator Training and Support: Provide comprehensive training for machine operators and maintenance staff to maximize the benefits of intelligent transmission solutions. Continuous support and training can ensure that your team effectively utilizes these technologies.A textile machinery manufacturer provided ongoing training and support to its clients, resulting in a 20% increase in operator efficiency and a 40% reduction in maintenance-related downtime.

Environmental Sustainability: Consider the environmental impact of your solutions. Develop eco-friendly transmission components and practices, such as using recyclable materials and reducing waste in manufacturing processes.A textile machinery manufacturer adopted sustainable manufacturing practices, reducing water and energy consumption in their production processes. This commitment to sustainability not only reduced their environmental footprint but also attracted eco-conscious customers.

Collaborative Robotics: Explore the use of collaborative robots (cobots) in the textile industry. These robots can work alongside human operators, performing tasks like material handling and quality control, further enhancing efficiency.Textile companies have incorporated collaborative robots into their manufacturing lines to handle repetitive tasks, such as fabric cutting and quality inspection. These cobots work alongside human operators, improving productivity and safety.

-

Authenticated user

-

Authenticated user

JIE intelligent transmission solution releases JIE intelligent transmission solution

hot news

- Research丨Lv Tie, a researcher from the Academy of Social Sciences, visited JIE for research and guidance >

- Academician|Mathematician Academician Sun Binyong inspects JIE future factory >

- Research | Lu Wuhu, vice chairman of the Municipal Federation of Trade Unions, investigates the JIE future factory >

- Research | Li Yongwei, Director of the Technological Innovation Department of the Provincial Department of Economics and Information Technology, investigates the future factory of JIE >

- Research | District Science and Technology Bureau Secretary Cao Xiaoxiang investigates JIE future factory >

- 33 | There is a kind of happiness called party care >

-

- Sharing Center

- Member Sharing

- Exclusive Sharing

- Public Sharing

Official Website

Official Tiktok

Official WeChat

Copyright © 2022 Hangzhou Jie Drive Technology Co., Ltd. Zhejiang ICP No. 16044538-4

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat