JIE intelligent transmission solution releases JIE intelligent transmission solution

complete information

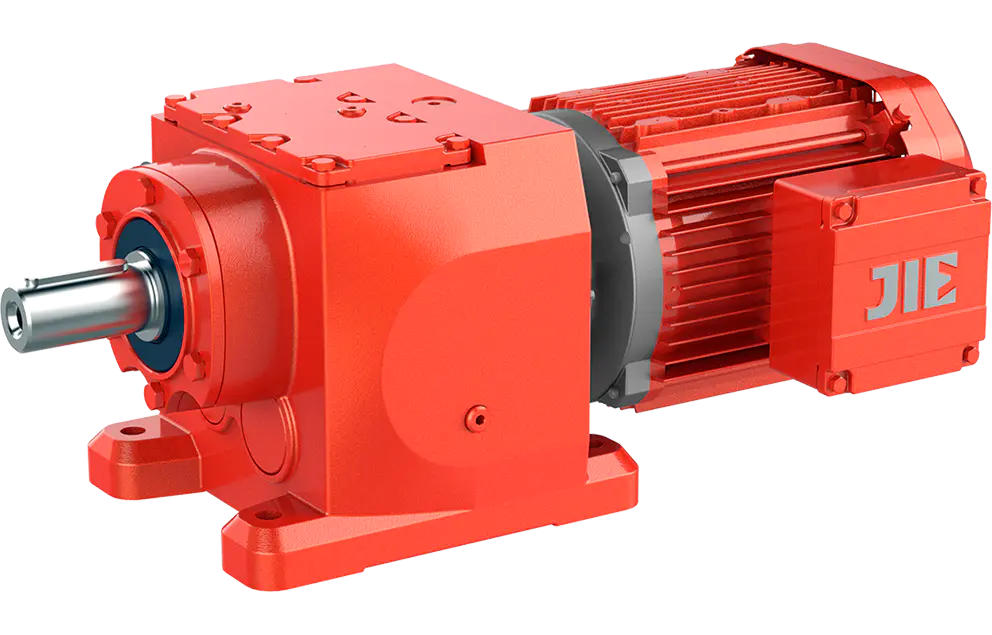

Inline vs. Right-Angle Gearboxes: A Gear Manufacturer's Perspective

As a leading manufacturer of gearboxes, we understand the critical role these components play in transferring power efficiently and achieving desired motion control. When it comes to choosing between inline and right-angle gearboxes, the decision hinges on a nuanced understanding of their functionalities and limitations.

As the name suggests, the primary difference lies in the orientation of the input and output shafts.

Inline Gearboxes (Parallel Shaft Gearboxes): These workhorses feature input and output shafts that are coplanar and parallel to each other. This allows for a straight-through transmission of power, making them ideal for applications with limited spatial constraints.

Right-Angle Gearboxes: Here, the input and output shafts are at a perpendicular (90-degree) angle. This enables a change in direction of power transmission, perfect for situations where space limitations necessitate a right-angle turn.

While orientation is the defining characteristic, several other factors differentiate these two gearbox types:

Efficiency: Inline gearboxes generally offer higher efficiency due to simpler gear arrangements. Right-angle gearboxes, particularly those using worm gears, may experience some efficiency losses due to the sliding contact between the worm and wheel.

Speed and Torque: Inline gearboxes can handle higher input speeds efficiently. Right-angle gearboxes, especially worm drives, excel at providing significant torque reduction at the output.

Load Capacity: Inline gearboxes can typically handle higher radial loads on the shafts due to their simpler design. Right-angle gearboxes may be limited in radial load capacity.

1. Gear Technology and Efficiency:

Inline Gearboxes: We primarily utilize spur gears and helical gears in inline gearboxes. These gears offer high efficiency (often exceeding 95%) due to their rolling contact, minimizing friction losses. For instance, in a recent project involving a conveyor belt system, our high-efficiency inline gearbox with helical gears significantly reduced energy consumption compared to a worm gear alternative.

Right-Angle Gearboxes: Here, the story becomes more diverse. We offer options with bevel gears, worm gears, and even planetary gearsets arranged in a right-angle configuration. While bevel gears offer decent efficiency (around 85-90%), worm gears experience higher sliding friction, leading to lower efficiency (typically 70-80%). However, worm gears excel in torque reduction, making them ideal for applications like material handling screw feeders. In a case study involving a bottling plant, our right-angle worm gearboxes provided the necessary torque multiplication to handle heavy bottle caps efficiently.

2. Speed and Load Capacity:

Inline Gearboxes: These excel at handling higher input speeds due to their simpler design and minimal sliding contact. Additionally, the coplanar shafts allow for efficient transmission of radial loads on the shafts. For instance, our high-speed inline gearboxes are a popular choice for applications like textile machinery where high rotational speeds and radial bearing loads are prevalent.

Right-Angle Gearboxes: While speed limitations exist, particularly with worm gears, right-angle gearboxes can achieve sufficient speeds for many applications. Their true strength lies in torque reduction. The right-angle configuration and gear geometry allow for significant multiplication of torque at the output, making them ideal for low-speed, high-torque applications. Additionally, some right-angle gearboxes, especially those with planetary gearsets, can handle higher radial loads compared to worm gear designs.

3. Cost and Applications:

Inline Gearboxes: Due to their simpler design and higher production volumes, inline gearboxes are generally a more cost-effective option. Their strengths in efficiency, speed handling, and radial load capacity make them ideal for applications like:

Conveyor belts

Material handling systems

Textile machinery

Machine tools (for specific axes)

Right-Angle Gearboxes: While often slightly more expensive, right-angle gearboxes offer a unique advantage in changing the direction of power transmission. Their strengths in torque reduction and suitability for some axial loads make them perfect for applications like:

Mixing equipment

Packaging machinery

Screw feeders

Robotics (for specific joints)

By understanding these technical nuances and drawing on real-world examples, we, as a gearbox manufacturer, can empower you to make an informed decision. Remember, the ideal choice hinges on your specific application's needs for speed, torque, efficiency, load capacity, and spatial constraints. Contact us for your ideal gear solution.

-

Authenticated user

-

Authenticated user

JIE intelligent transmission solution releases JIE intelligent transmission solution

hot news

- Research丨Lv Tie, a researcher from the Academy of Social Sciences, visited JIE for research and guidance >

- Academician|Mathematician Academician Sun Binyong inspects JIE future factory >

- Research | Lu Wuhu, vice chairman of the Municipal Federation of Trade Unions, investigates the JIE future factory >

- Research | Li Yongwei, Director of the Technological Innovation Department of the Provincial Department of Economics and Information Technology, investigates the future factory of JIE >

- Research | District Science and Technology Bureau Secretary Cao Xiaoxiang investigates JIE future factory >

- 33 | There is a kind of happiness called party care >

-

- Sharing Center

- Member Sharing

- Exclusive Sharing

- Public Sharing

Official Website

Official Tiktok

Official WeChat

Copyright © 2022 Hangzhou Jie Drive Technology Co., Ltd. Zhejiang ICP No. 16044538-4

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat