JIE intelligent transmission solution releases JIE intelligent transmission solution

complete information

Gear Motors: Unveiling the Mechanics and Applications

Unraveling the World of Gear Motors

Gear motors, the dynamic duo of motors and gearboxes, are the unsung heroes powering a multitude of industrial and commercial applications.

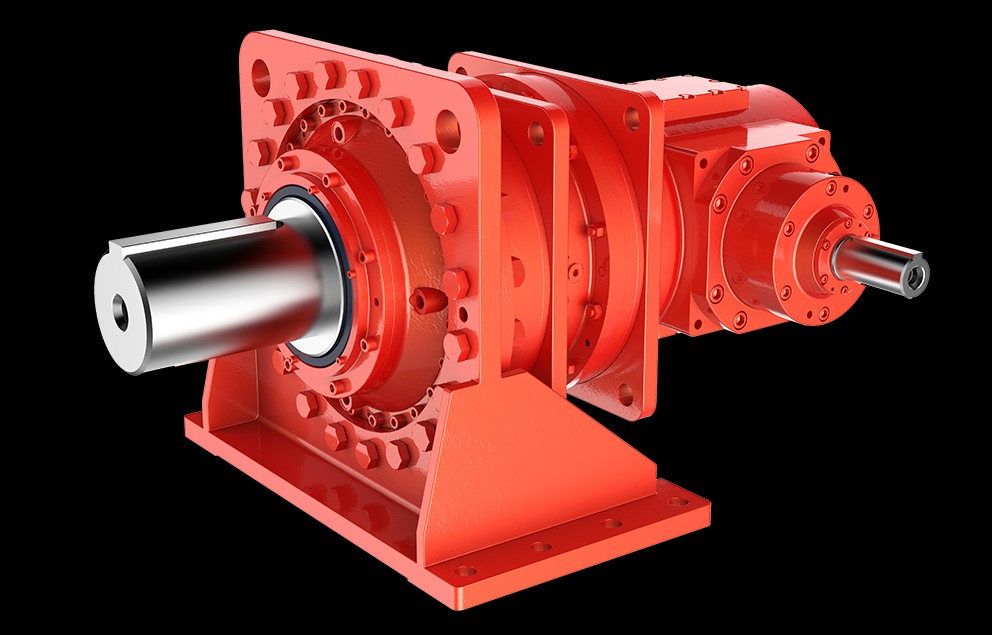

1. Planetary Gear Motors

Planetary gears, featuring a central sun gear surrounded by planet gears and an outer ring gear, exemplify precision and versatility. Widely employed in robotics, CNC machinery, and aerospace systems, planetary gear motors offer a perfect blend of compact design and high torque capabilities.

Applications:

Robotics

CNC machinery

Aerospace systems

2. Cycloidal Gear Motors

Cycloidal gears, with their cam and pinwheel mechanisms, bring unparalleled smoothness to motion control applications. Embraced in robotics, medical equipment, and printing machinery, cycloidal gear motors excel in delivering precise and reliable performance.

Applications:

Robotics

Medical equipment

Printing machinery

3. Parallel Shaft Gear Motors

With two parallel shafts and gears meshing between them, parallel shaft gear motors find their niche in diverse industrial applications. From pumps and compressors to material processing and mining equipment, these gear motors provide the torque and speed required for heavy-duty tasks.

Applications:

Pumps and compressors

Material processing

Mining equipment

4. High-Speed Gear Motors

For applications demanding a need for speed, high-speed gear motors step up to the plate. Embraced in electric vehicles, aerospace applications, and high-speed machinery, these motors provide the velocity and precision required for cutting-edge technology.

Applications:

Electric vehicles

Aerospace applications

High-speed machinery

5. Low-Speed Gear Motors

On the flip side, low-speed gear motors are the workhorses when it comes to torque. Ideal for winches, hoists, and heavy-duty machinery, these motors ensure a powerful performance where slow and steady wins the race.

Applications:

Winches and hoists

Conveyor systems

Heavy-duty machinery

Mastering the Basics: Spur, Bevel, and Worm Gears

1. Spur Gears: The Common Workhorses

Straight teeth, parallel axes, and a cost-effective solution—spur gears are the backbone of many mechanical systems. From clocks to power stations, these gears find a home in diverse applications.

Applications:

Clocks

Pumps

Material handling equipment

2. Bevel Gears: The Cornerstone of Right Angles

Bevel gears bring right-angle configurations to the forefront. Durable and available in various tooth designs, they shine in applications demanding precision and strength.

Applications:

Printing presses

Marine propulsion systems

Material processing equipment

3. Worm Gears: Precision in Motion

Known for their high precision and self-locking mechanisms, worm gears navigate the challenges of non-parallel and non-intersecting shafts. The quiet achievers in machinery requiring substantial speed reduction.

Applications:

Elevators and lifts

Rolling mills

Textile machinery

Gear Motors in Action: Applications Galore

Gear motors, with their versatility, extend their influence across diverse applications. While industrial gear motors find their footing in automated door operators and food and beverage machines, DC gear motors power through vehicle industries. From jacks and cranes to elevators and automation systems, gear motors are the unsung heroes driving efficiency in myriad processes.

-

Authenticated user

-

Authenticated user

JIE intelligent transmission solution releases JIE intelligent transmission solution

hot news

- Research丨Lv Tie, a researcher from the Academy of Social Sciences, visited JIE for research and guidance >

- Academician|Mathematician Academician Sun Binyong inspects JIE future factory >

- Research | Lu Wuhu, vice chairman of the Municipal Federation of Trade Unions, investigates the JIE future factory >

- Research | Li Yongwei, Director of the Technological Innovation Department of the Provincial Department of Economics and Information Technology, investigates the future factory of JIE >

- Research | District Science and Technology Bureau Secretary Cao Xiaoxiang investigates JIE future factory >

- 33 | There is a kind of happiness called party care >

-

- Sharing Center

- Member Sharing

- Exclusive Sharing

- Public Sharing

Official Website

Official Tiktok

Official WeChat

Copyright © 2022 Hangzhou Jie Drive Technology Co., Ltd. Zhejiang ICP No. 16044538-4

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat