JIE intelligent transmission solution releases JIE intelligent transmission solution

complete information

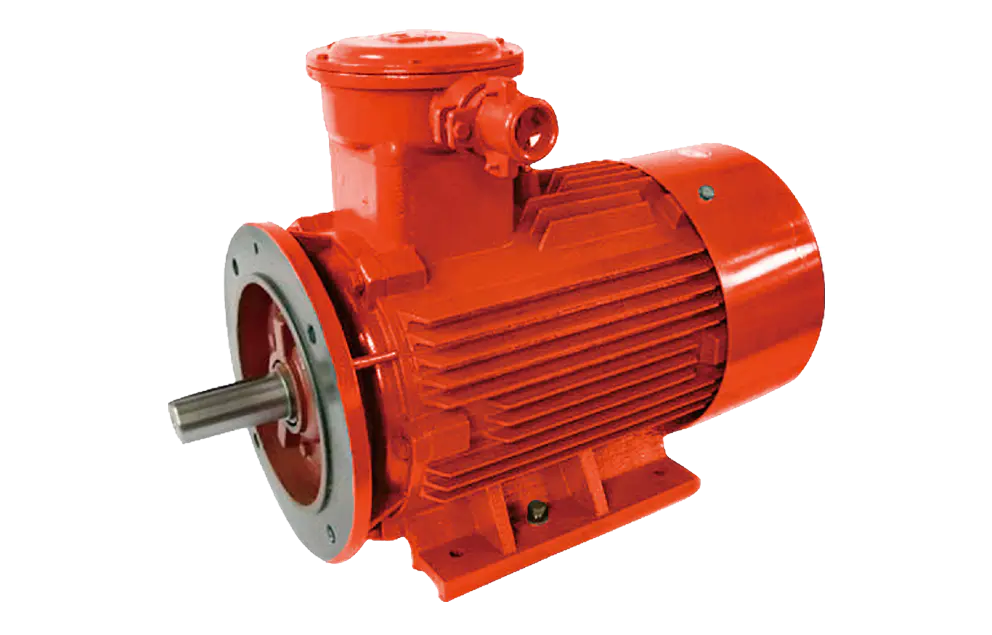

Explosion-proof Motors: Principles, Prevention Methods, and Selection Guide

Explosion-proof motors are specially designed electric motors that can safely operate in hazardous locations where flammable gases, vapors, or dusts are present. They are constructed to prevent internal sparks, arcs, or heat from igniting the surrounding explosive atmosphere. Explosion-proof motors are crucial in various industries, including:

Chemical processing

Oil and gas production

Grain processing

Mining

Woodworking

Textiles

Working Principle of Explosion-proof Motors

The explosion-proofing principle of explosion-proof motors is to prevent sparks, arcs, or heat from escaping the motor's interior and igniting the surrounding explosive mixture. This is achieved through various methods:

Explosion-proof enclosures: The most common type of explosion-proof motor. The motor housing is made of robust metal that can withstand an internal explosion. The gaps at the joints are minimal, preventing flames or hot gases from escaping.

Increased safety motors: Designed to limit the generation of sparks, arcs, and heat within the motor. They typically have smaller housing gaps and utilize special materials and designs to reduce spark hazards.

Pressurized motors: Prevent explosive mixtures from entering the motor enclosure by pressurizing it. The pressure maintains a positive atmosphere around the motor, even if the enclosure leaks, preventing explosive mixtures from entering.

Non-sparking motors: Employ electrical components designed not to produce sparks. This includes induction motors and permanent magnet motors.

Dust-proof explosion-proof motors: Designed to prevent combustible dust from entering the motor and causing an explosion. They often feature sealed enclosures and special cooling systems.

Selection Guide for Explosion-proof Motors

When selecting an explosion-proof motor, consider the following factors:

Hazardous area classification: Hazardous areas are classified based on the explosion hazard of the present flammable gases or dusts. The motor must be rated for the specific hazardous area in which it will be used.

Explosion-proof type: Different types of explosion-proof motors are discussed above. It is crucial to choose the type most suitable for the application.

Motor performance: Factors like power, speed, and torque must meet the application requirements.

Environmental factors: Consider factors like temperature, humidity, and corrosiveness.

Certification: Ensure the motor is certified by a qualified organization, such as UL or CSA.

Maintenance of Explosion-proof Motors

Regular maintenance is essential for explosion-proof motors to ensure their proper operation and prevent explosion hazards. Maintenance tasks include:

Inspecting the motor housing for damage.

Checking for excessive gaps at the joints.

Cleaning dust and debris from the motor's interior.

Examining electrical components for wear or damage.

Lubricating as per the manufacturer's recommendations.

Conducting electrical performance testing routinely.

Following these maintenance guidelines will help ensure the safe and reliable operation of explosion-proof motors.

-

Authenticated user

-

Authenticated user

JIE intelligent transmission solution releases JIE intelligent transmission solution

hot news

- Research丨Lv Tie, a researcher from the Academy of Social Sciences, visited JIE for research and guidance >

- Academician|Mathematician Academician Sun Binyong inspects JIE future factory >

- Research | Lu Wuhu, vice chairman of the Municipal Federation of Trade Unions, investigates the JIE future factory >

- Research | Li Yongwei, Director of the Technological Innovation Department of the Provincial Department of Economics and Information Technology, investigates the future factory of JIE >

- Research | District Science and Technology Bureau Secretary Cao Xiaoxiang investigates JIE future factory >

- 33 | There is a kind of happiness called party care >

-

- Sharing Center

- Member Sharing

- Exclusive Sharing

- Public Sharing

Official Website

Official Tiktok

Official WeChat

Copyright © 2022 Hangzhou Jie Drive Technology Co., Ltd. Zhejiang ICP No. 16044538-4

English

English 简体中文

简体中文

Official Tiktok

Official Tiktok Official WeChat

Official WeChat